Seed Cotton Handling Storage

Forming Covering Conventional Modules

Figure 9 A well-drained site clear of weeds and cotton stalks and easily accessible by boll buggy or harvester should be selected to build modules.

Maximum seed cotton protection during storage is related to module site selection, along with construction and covering the module to prevent water penetration. The module building sites should be on well drained areas such as turn rows or field roads (Figure 9).

Under wet conditions, low areas will collect water and saturate the bottom layer of the module, causing deterioration of seed cotton. The site should be smooth and firm, free of rocks, clods, and vegetation such as cotton stalks and grass. Do not build modules on stalks or tall vegetation, as they will be picked up with the module in the loading process. Ginning may not remove all foreign matter, resulting in contaminated lint and reduced lint grades. The site should be easily accessible by the harvester or boll buggy and clear of overhead obstructions such as utility lines or trees. If possible, the site should be accessible to module trucks during wet weather. If possible, modules should be built in an area away from heavily traveled roads, thus away from possible sources of fire and vandalism.

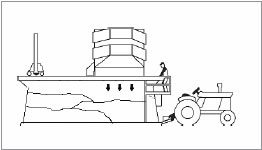

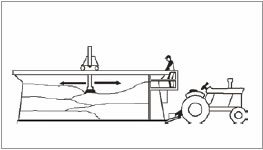

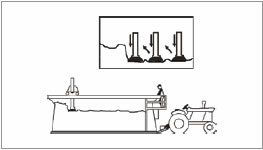

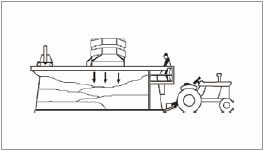

Figure 10 Procedures for forming a seed cotton module in a module builder.

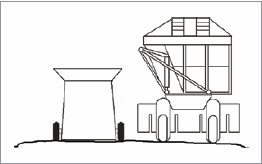

Figure 10a Upon completion of the cotton module, the rear door is opened, the module raised on the transport wheels and the tractor is driven forward to move the builder off the module and to the location for the next module.

Figure 10b As more cotton is added to the chamber, the tramper should be used to move cotton along the length of the chamber to achieve uniform loading.

Figure 10c The cotton should be compressed with a series of actions with the tramper to uniformly pack the entire chamber.

Figure 10d When the module is nearly completed, move cotton to the ends to provide space for the last dump and to form solid ends.